ABOUT JOGINDRA

Established in 1959 by S. Joga Singh Mudarh, Jogindra Engineering Works Pvt. Ltd. has been a pioneer in manufacturing plastic processing and recycling machines for over six decades. With a commitment to innovation and excellence, Jogindra specializes in designing and producing high-quality equipment such as Heating Cooling Mixers, High Speed Mixers, Container Mixers, Scrap Granulators, Single-Shaft Shredders, Two-Shaft Shredders, Four-Shaft Shredders, Pulverisers, Lab Mixers, Gelimat Mixers, Ribbon Blenders, Plastisol Mixers, Material Handling systems / Batch conveying systems (semi or fully automatic) like Vacuum conveying, screw conveying, spring conveying

Headquartered in New Delhi, India, Jogindra has expanded its presence with offices in Gurgaon, Bhiwadi and Ahmedabad, catering to both domestic and international markets. Our state-of-the-art manufacturing units are strategically located in Bhiwadi, Rajasthan (Unit-1) spread across 8,000 sq. meters and Ahmedabad, Gujarat,(Unit-2) ensuring high production efficiency and quality control. Our dedication to technological innovation, superior craftsmanship, and customer satisfaction has positioned us as a trusted name in the industry, serving clients across India and worldwide.

ProductsTrusted Leaders in Plastic Processing Machines Since 1959

PVC Mixer

Efficient PVC mixers for precise blending, ensuring high-quality consistent results in PVC processing and manufacturing applications.

Powder Coating

Advanced powder coating machines providing smooth, durable finishes for a wide range of industrial applications and products.

Master batches and Pigments

Precision-engineered solutions for masterbatches and pigments, ensuring uniform blending and high quality results in plastic processing applications.

Wood Plastic Composites

Efficient machines for manufacturing durable, eco-friendly wood plastic composites, blending strength and sustainability for modern applications.

Other Applications

Versatile machines for various industrial applications, delivering precision efficiency across diverse plastic processing needs.

Laboratory Mixers

Precision laboratory mixers designed for consistent, efficient blending, ensuring accurate results in small-scale plastic processing.

What we doDelivering Excellence in Plastic Processing Solutions

We utilize advanced CAD/CAM technology to design cutting-edge plastic processing machines, ensuring precision, efficiency, and durability.

With over 6000 installations worldwide, we cater to diverse industries, delivering customized solutions and reliable machinery.

Our experienced team provides end-to-end support, from consultation to after-sales service, ensuring customer satisfaction and repeat trust.

We have worked for you

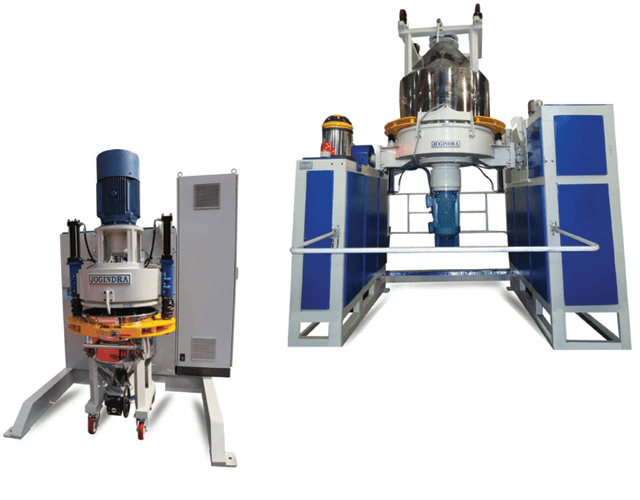

ProductsHEATING COOLING MIXER HORIZONTAL (JHCH)

Jogindra Heating Cooling Mixer – Horizontal is a combination of High Speed Mixer and Cooling Mixer in Horizontal construction. The materials in High Speed Mixer is heated by utilization of frictional heat and subsequently the heated compound is transferred to Horizontal Cooling Mixer which cools the material faster by special cooling blades combination of radial and axial design, allowing an increase in the number of batches per hour. The cooling water consumption is reduced, maintenance costs are also lesser. This horizontal construction Cooling Mixer can be fitted to any type of mixer in accordance with customer’s requirements.

- 120°C of Heating Mixer

- 45°C for Cooling Mixer

- Direct current motors

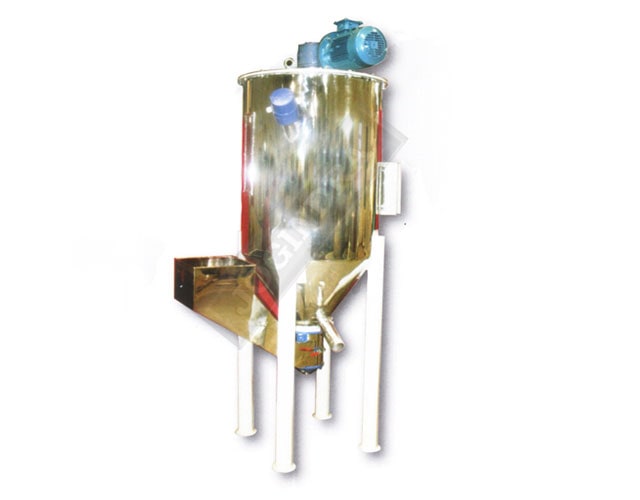

ProductsPULVERIZER (JPZ)

JOGINDRA, Blade Pulverizer is specially designed to reprocess the rejects to convert into free flowing powder. It is suitable for rigid PVC i.e. Profiles,Pipes,Sheets and Injection moulding rejects.

The feed material should be pre-grinded into 4 to 6 mm size. The Pulverizer provides hammering and milling action in between toothed rotary and fixed segments. The specially designed toothed milling geometry is a result of our constant development on our part for three decades.

Model

JPZ-100

Size of feed Material

4-6 mm

Connected Motor

30 HP

Production rate

80-100 (kg/hr)

Final size of Granules

100 microns approx.

News & EventsNews & Events

K-2019Date-16th to 23rd October 2019

Visit us at K-2019, Dusseldorf, Germany at Stall-B-76, Hall No. 9

IPF-2019Date- 17th to 20th January 2019

International Plastics, Printing and Packaging Industry Fair

Plastindia 2018Date-7th to 12th February 2019

Ahmedabad, Gujarat, India

Stall D 102, Hall No. 8