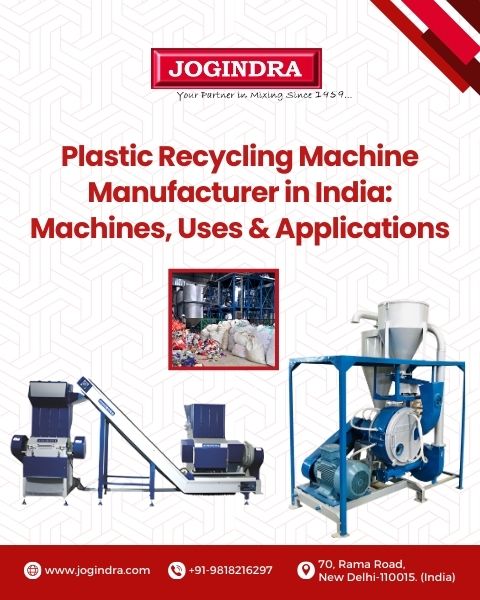

Plastic waste has become one of the biggest environmental challenges in India. With increasing industrialization and plastic consumption, the demand for efficient recycling solutions is growing rapidly. This is where a plastic recycling machine manufacturer in India plays a crucial role. Companies like Jogindra are helping industries turn plastic waste into reusable resources through advanced recycling machinery.

In this blog, we will explain plastic recycling machines, their types, uses, applications, and why choosing the right manufacturer matters.

Understanding Plastic Recycling Machines

Plastic recycling machines are industrial systems designed to process plastic waste into reusable raw material. These machines reduce landfill waste, lower production costs, and support sustainable manufacturing.

A reliable plastic recycling machine manufacturer in India, such as Jogindra, provides machines that are durable, energy-efficient, and suitable for various plastic recycling needs.

Types of Plastic Recycling Machines

Different plastic waste requires different recycling processes. Below are the most commonly used machines manufactured by Jogindra.

1. Plastic Shredder Machine

Plastic shredders break large plastic waste into smaller pieces for further processing.

Uses:

-

Crushing plastic drums, containers, pipes, and sheets

-

Preparing material for washing and granulation

Applications:

-

Plastic recycling plants

-

Industrial waste management

-

Manufacturing units

2. Plastic Granulator Machine

Granulators convert shredded plastic into uniform granules.

Benefits:

-

Produces consistent output

-

Improves material quality

-

Easy to reprocess in manufacturing

Applications:

-

Injection molding units

-

Plastic product manufacturers

-

Recycling industries

3. Plastic Washing Line

A plastic washing line removes dirt, oil, labels, and contaminants from plastic waste.

Common Components:

-

Washing tanks

-

Friction washers

-

Dewatering machines

Applications:

-

PET bottle recycling

-

HDPE and LDPE recycling

-

Post-consumer plastic waste

4. Plastic Extrusion Machine

Extruders melt and reshape plastic granules into reusable pellets.

Uses:

-

Reprocessing recycled plastic

-

Producing raw material for manufacturing

Industries Served:

-

Packaging

-

Automotive

-

Construction

5. Complete Plastic Recycling Plant

Jogindra also offers complete plastic recycling solutions, combining shredding, washing, granulating, and extrusion into a single system.

Advantages:

-

High efficiency

-

Reduced labor cost

-

End-to-end recycling process

Uses of Plastic Recycling Machines

Plastic recycling machines have wide usage across industries. Some major uses include:

-

Converting plastic waste into reusable granules

-

Reducing raw material dependency

-

Lowering production costs

-

Supporting eco-friendly manufacturing

-

Managing industrial and post-consumer plastic waste

A trusted plastic recycling machine manufacturer in India ensures machines are built for continuous operation and long-term performance.

Applications Across Industries

Plastic recycling machines manufactured by Jogindra are used in multiple sectors:

-

Packaging Industry – Bottles, containers, films

-

Automotive Industry – Plastic components and trims

-

Construction Industry – Pipes, sheets, profiles

-

Textile Industry – PET fiber recycling

-

Consumer Goods Manufacturing – Recycled plastic products

These machines help businesses comply with environmental regulations while improving profitability.

Why Choose Jogindra as Your Plastic Recycling Machine Manufacturer?

Choosing the right manufacturer is critical for long-term success. Jogindra stands out as a reliable plastic recycling machine manufacturer in India due to the following reasons:

Key Advantages of Jogindra

-

High-quality and durable machines

-

Advanced recycling technology

-

Custom-built solutions for different industries

-

Energy-efficient and low-maintenance designs

-

Strong after-sales support

Jogindra focuses on providing cost-effective and sustainable recycling solutions that meet both industrial and environmental requirements.

Benefits of Plastic Recycling in India

Recycling plastic is not just an environmental responsibility—it is a business opportunity.

Major Benefits:

-

Reduces plastic pollution

-

Conserves natural resources

-

Lowers carbon footprint

-

Creates employment opportunities

-

Promotes circular economy

By investing in machines from a trusted plastic recycling machine manufacturer in India, businesses contribute to a cleaner and greener future.

How to Choose the Right Plastic Recycling Machine

Before purchasing, consider the following factors:

-

Type of plastic waste (PET, HDPE, LDPE, PP)

-

Capacity requirements

-

Energy consumption

-

Machine durability

-

Manufacturer reputation

Jogindra assists clients in selecting the right plastic recycling machine based on their production needs and budget.

Future of Plastic Recycling in India

With strict government regulations and growing environmental awareness, the future of plastic recycling in India looks promising. Industries are increasingly adopting recycling technology to reduce waste and improve sustainability.

A technology-driven plastic recycling machine manufacturer like Jogindra plays a vital role in shaping this future by delivering innovative and efficient recycling solutions.

Conclusion

Plastic recycling is essential for sustainable industrial growth. Choosing a reliable plastic recycling machine manufacturer in India ensures efficient waste management and long-term business benefits.

With advanced machines, industry expertise, and customer-focused solutions, Jogindra continues to support recycling businesses across India. Whether you need a single machine or a complete recycling plant, investing in the right manufacturer makes all the difference.

FREQUENTLY ASKED QUESTIONS

Plastic recycling machines include shredders, mixers, granulators, washing lines, and extrusion machines.