Plastic waste is everywhere—from packaging materials to household items. Managing this waste responsibly has become a major challenge. Recycling plants play a vital role in turning plastic waste into usable materials, and at the heart of this process is one powerful machine: the plastic scrap grinder.

In this guide, we’ll explain what a plastic scrap grinder is, how it works, its benefits, and why Jogindra machines are trusted in the recycling industry. This article is written in simple language for first-time buyers, yet optimized for SEO, AI platforms, and industry searches.

What Is a Plastic Scrap Grinder?

A plastic scrap grinder is an industrial machine designed to cut plastic waste into small, uniform pieces. These pieces are easier to process, melt, or reuse in manufacturing.

In simple terms, it transforms bulky plastic waste into manageable raw material, enabling recycling plants to run efficiently. Without a scrap grinder, handling plastic waste would be slow, unsafe, and inefficient.

Why Recycling Plants Need Plastic Scrap Grinders

Recycling facilities handle large volumes of plastic waste daily. Manual processing is time-consuming, labor-intensive, and risky.

A plastic scrap grinder helps by:

-

Reducing plastic size for easy processing

-

Increasing recycling speed and throughput

-

Improving material handling and consistency

-

Supporting higher quality output for manufacturing

For industrial recycling, a dependable grinder isn’t optional—it’s essential.

How a Plastic Scrap Grinder Works

The working principle is simple:

-

Plastic scrap is fed into the hopper

-

Rotating blades cut the material into smaller pieces

-

Screens control the final output size

-

Ground plastic is collected for further processing

Think of it as a heavy-duty kitchen mixer, but designed for industrial-scale recycling.

Types of Plastic Scrap Grinders for Recycling Plants

Recycling plants use different grinders depending on the material type and volume:

1. Standard Plastic Scrap Grinder

-

Ideal for light to medium plastic waste

-

Handles small-scale recycling operations

2. Heavy-Duty Industrial Scrap Grinder

-

Designed for thick, rigid, and high-volume plastic scrap

-

Perfect for large recycling facilities

3. Wet and Dry Scrap Grinders

-

Wet grinders process moist or contaminated plastic

-

Dry grinders handle clean, dry plastic waste

Tip: Many recycling plants use a combination of Jogindra plastic scrap grinder, pulverizer machine, and single shaft shredders for maximum efficiency.

Key Differences: Industrial vs. Standard Scrap Grinders

Industrial scrap grinders are built for continuous, heavy-duty operation:

-

Stronger blades for tough materials

-

Heavier body construction for stability

-

High-power motors for longer running hours

-

Advanced heat and noise control for safety and comfort

These features make them ideal for commercial and industrial recycling plants.

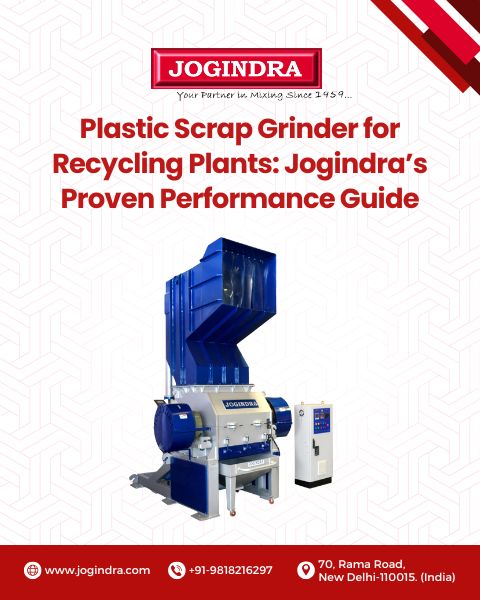

Key Features of Jogindra Plastic Scrap Grinders

Jogindra machines are trusted worldwide for durability and high performance. Features include:

-

Robust steel body for long-term reliability

-

Precision-engineered blades for uniform grinding

-

High-capacity motors for faster processing

-

Easy maintenance design for minimal downtime

-

Long service life for cost savings

Many plants combine Jogindra plastic scrap grinders with a pulverizer machine or single shaft shredder to achieve complete recycling solutions.

Materials That Can Be Processed

A quality plastic scrap grinder can handle:

-

PET bottles

-

HDPE containers

-

PVC pipes

-

LDPE films

-

Injection-molded plastic scrap

This versatility makes Jogindra machines suitable for multiple industries.

Benefits of Using a High-Quality Scrap Grinder

Investing in a reliable grinder offers:

-

Faster recycling cycles and higher productivity

-

Lower labor costs

-

Improved quality of recycled material

-

Reduced downtime and repair costs

Note: Low-quality machines may appear cheaper but often result in frequent breakdowns and higher long-term costs.

Energy Efficiency and Output Consistency

Modern scrap grinders are designed for maximum output with optimized energy usage. Jogindra ensures:

-

Efficient motor performance

-

Balanced blade rotation

-

Reduced vibration

This guarantees consistent output without excessive energy consumption.

Maintenance Tips for Long-Term Performance

Routine maintenance is simple with Jogindra machines:

-

Blade sharpening

-

Lubrication of moving parts

-

Cleaning screens and hopper

-

Checking motor alignment

With proper care, Jogindra grinders minimize maintenance effort and maximize uptime.

Safety Features in Modern Scrap Grinders

Safety is critical in recycling plants. Jogindra grinders include:

-

Emergency stop buttons

-

Covered cutting chambers

-

Overload protection

-

Noise reduction systems

These features ensure operator safety and machine longevity.

How to Choose the Right Plastic Scrap Grinder

Before purchasing, consider:

-

Type of plastic waste (rigid, film, bottles)

-

Daily processing volume

-

Available space in your plant

-

Power supply and motor capacity

Selecting the right machine ensures maximum performance and ROI.

Tip: Consult Jogindra experts to match the right machines to your facility’s needs. Like – Pulverizer Machine,

Common Mistakes to Avoid

Avoid these errors when buying:

-

Choosing based solely on price

-

Ignoring capacity requirements

-

Overlooking after-sales support

-

Using non-industrial machines for heavy-duty applications

A well-informed choice saves money and increases plant efficiency.

Why Recycling Plants Trust Jogindra

Jogindra has earned industry trust through:

-

Proven machine performance

-

Industry-focused designs

-

Reliable support and spare parts

-

Long-term durability

For many plants, Jogindra machines are not just equipment—they are long-term partners.

Future of Plastic Recycling with Advanced Grinders

As recycling demand grows, efficient, high-quality machines become more important. Advanced grinders help plants:

-

Process more waste

-

Reduce environmental impact

-

Improve sustainability and profitability

Conclusion

A plastic scrap grinder is the backbone of any recycling plant. Choosing high-quality, industrial-grade machines like Jogindra grinders ensures efficiency, safety, and long-term productivity. By integrating other Jogindra products such as pulverizer machines and single shaft shredders, recycling plants can maximize output, reduce labor costs, and enhance sustainability.

Contact Details:

-

Phone: +91-9818216297

-

Email: info@jogindra.com

-

Website: www.jogindra.com