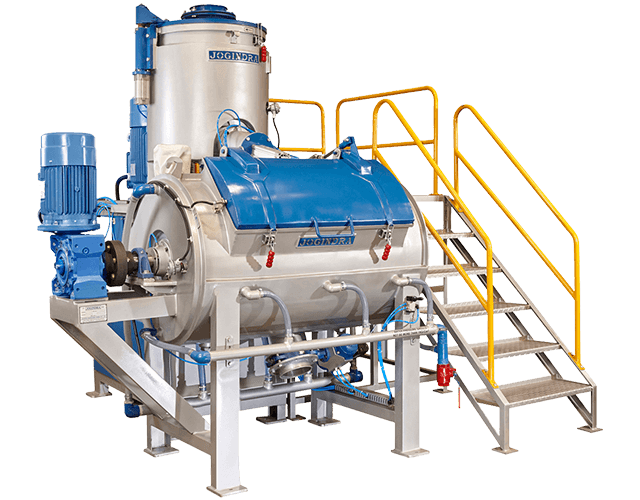

Horizontal Heating Cooling Mixer (JHCH)

Jogindra Horizontal Heating Cooling Mixer is an advanced heating cooler mixer designed with a combination of High Speed Mixer and Cooling Mixer in horizontal construction. It is widely used in PVC compounding, masterbatch production, UPVC & C-PVC pipe processing, cable manufacturing, and WPC industry applications. The High Speed Mixer heats raw material through frictional heat, while the Horizontal Cooling Mixer cools it efficiently with radial and axial blades. This design ensures uniform mixing, reduced water and energy consumption, low maintenance, and increased batch output per hour. Trusted as durable plastic processing equipment, it is the perfect solution for manufacturers seeking a reliable PVC compounding machine, masterbatch mixer, or UPVC pipe mixer for consistent quality and productivity.